Most of the time this has to do with how the material was cut.

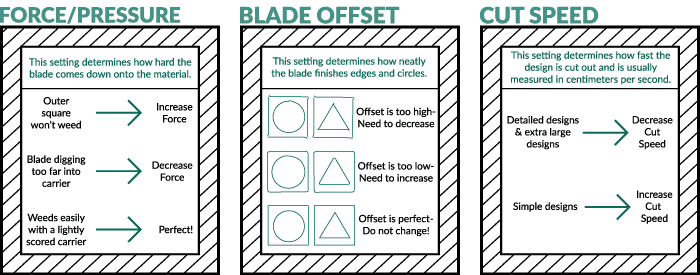

Before plotting your design, perform test cuts and adjust blade depth and speed accordingly.

Click HERE to download an infographic concerning what to look for in a test cut for the perfectly plotted design every time.

If the blade is not connecting the lines in the design, the blade offset degree should be adjusted on the plotter to make the edges of the design join properly.

When doing a test cut, make sure the machine is cutting 90° angles in the outer box, and depending on your cutter, you will have either a circle or a triangle inside the square